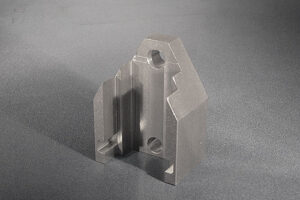

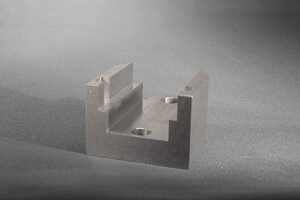

Milling of Aluminum Machine Components

The Rayflex Company was approached by a customer from the printing industry to mill 40 aluminum machine components. The components were made of 2024 aluminum and measured 2.5″ long, 2″ wide and 1.25″ high. Each of the aluminum machinery components were milled, drilled and bored all while holding tightest tolerances of ±.005″ throughout the entire process. We then 100% dimensionally inspected each piece and shipped them to the client’s Connecticut location. The entire process took the experts at Rayflex 2 to 3 weeks to complete.

If you have any questions about this milling project, please see the details below. For more information on all our other services please contact Rayflex, today.

Milling of Aluminum Machine Components Project Highlights

- Product Description

These aluminum components were used within a printing machine.

- Capabilities Applied/Processes

- Milling

Drilling - Boring

- Milling

- Overall Aluminum Machine Component Dimensions

-

Length: 2.500″

Width: 2.000″ - Height: 1.250″

-

Length: 2.500″

- Tightest Tolerances

±.005″

- Material Used

2024 Aluminum

- In process testing/inspection performed

100% Dimensional Inspection

- Industry for Use

Printing

- Volume

40

- Turn Around Time

2 to 3 Weeks

- Delivery Location

Connecticut

- Standards Met

Customer Supplied Print

- Product Name

Aluminum Machinery Component